|

|

|

HP C1557A DDS 3 Autoloader

Specification

| Apricot Part Number |

PT15904631 |

| Vendor |

H.P. |

| Series |

DDS 3 AL |

| Model |

C1557A |

| Form Factor |

5.25" HH |

| Height |

3.2" / 82mm |

| Width |

5.7" / 146mm |

| Length |

8.0" / 203.2mm |

| Weight |

4.8lbs / 2.2Kg |

| Tape Type |

DDS-3 125m 4mm DAT |

| Tape Length |

125m |

| Capacity Native |

6x12GB=72GB |

| Capacity Compressed @2:1 |

6x24GB=144GB |

| Recording Media |

MP++ |

| Cartridge Size (W x D) |

73 x 53mm |

| Flux Density |

152,500 ftpi |

| Tracks |

2,804 trks/inch |

Performance

| Transfer Rate, @ 2:1 Burst |

2MB/s |

| Transfer Rate, Native Burst |

1MB/s |

| Head to Tape Speed, Read / Write |

236 ips |

| Search / Rewind |

100x normal |

| Physical Interface |

SE 8bit SCSI |

| Logical Interface |

SCSI-2 |

| Maximum Transfer Rate |

5MB/s |

| Buffer Size |

2MB |

| Hardware Compression |

Yes, DCLZ |

| Recording Method |

Helical Scan |

| Recording Code |

DDS-DC |

| Error Recovery Type |

Reed S'mon C3 |

| Read after Write Verify |

Yes |

| Correctable Read Error Rate |

1 in 104 bits |

| Uncorrectable Read Error Rate |

1 in 1015 bits |

Environment

| Minimum Ambient operating Temperature |

5°C |

| Maximum Ambient operating Temperature |

45°C |

| Maximum Thermal Gradient |

2°C/minute |

| Average Power Consumption |

Combined |

| Operating Maximum |

28W |

| Nominal Read / Write |

9W |

| Nominal Idle |

9W |

| DC Power Requirements |

Combined |

| +12V Peak |

2.0Amps |

| +12V Operational Nominal |

0.2Amps |

| +5V Peek |

1.20Amps |

| +5V Stepping Head Nominal |

1.20Amps |

| MTBF |

55,000 poh |

Jumpers & Switches

SCSI ID

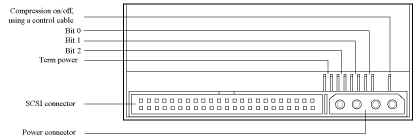

The SCSI ID is set using the jumpers on the set of pins beside the SCSI

connector at the rear of the drive, shown below:

SCSI Jumper Pins

The three significant bits in the ID give a range of 0 to 7 as follows:

| SCSI ID |

Bit 2 |

Bit 1 |

Bit 0 |

| 0 |

0 |

0 |

0 |

| 1 |

0 |

0 |

1 |

| 2 |

0 |

1 |

0 |

| 3 |

0 |

1 |

1 |

| 4 |

1 |

0 |

0 |

| 5 |

1 |

0 |

1 |

| 6 |

1 |

1 |

0 |

| 7 |

1 |

1 |

1 |

1 = shorted

0 = open

The drive reads the SCSI ID at power-up and during self-test.

Data Compression Control

Data compression can be controlled through the jumper pin shown above. The pin is only

monitored at power-on, and controls whether data compression is enabled by default. Any

subsequent change to the pin are ignored.

| Pin State |

Effect |

| Unconnected |

This is the default. Data compression is

controlled by the configuration switches 1 and 2 (on the underside of the drive) and

through the SCSI MODE SELECT command. |

| Connected to 0V |

Data compression is disabled. The

setting of configuration switch 1 is ignored. Switch 2 is valid. However, data compression

can still be controlled through MODE SELECT. Note that when reading, the drive will always

decompress compressed data

It follows from this that if you wish to use this pin, you should switch 1 on the

underside of the drive to ON |

Terminator Power

The drive will provide termination power for the SCSI termination resistors if a jumper is

set across the two pins marked "Term power" as shown in the diagram

Configuration switches

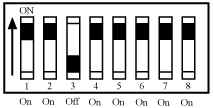

There is a set of configuration switches on the underside of the drive,

shown below:

With the drive switched off, use the information below to select the

correct configuration for your system.

Note

For the drive to operate correctly, appropriate drivers and application software must be

loaded on the host computer.

Data Compression

Switches 1 and 2 are normally used to configure the way in which data compression is set

for the drive. The following table shows the available options:

| Switch 1 |

Switch 2 |

Meaning |

| On |

On |

Compression enabled at power-on with host control |

| On |

Off |

Compression enabled at power-on no host control |

| Off |

On |

Compression disabled at power-on. The host is allowed

to control compression |

| Off |

Off |

Compression disabled at power-on no host control |

When switch 1 is on, data written to the tape will be compressed without

the knowledge of the host.

Media Recognition System (MRS)

Switch 3 is used to configure the drive to respond to DDS Media Recognition System tapes:

| Switch 3 |

Meaning |

| On |

The Media Recognition System is disabled. All DDS

tapes are treated the same, whether they posses the Media Recognition stripes or not. |

| Off |

The Media Recognition System is active. This is the

default setting. Non Media Recognition System tapes are treated as if they are

write-protected. |

Switches 4 to 8

Switches 4 to 8 are used to specify connectivity and functionality according to host or

customer requirements. The default settings for all switches is on.

Option switches

The autoloader option switches are on the rear-panel. The switches are

read at power-on. When the autoloader is switched off, you can set the following

configurations (other settings are not used at this time).

| 4 |

3 |

2 |

1 |

Value |

Auto-stack |

Auto-eject |

Allow

Resequencing |

LUN 1 Magazine

Ready |

LUN 0 Drive

Inquiry |

| On |

Off |

Off |

On |

1h |

Enabled |

Enabled |

|

|

|

| Off |

On |

On |

On |

6h (HP Series 800) |

|

|

Enabled |

Enabled |

Enabled |

| Off |

On |

On |

On |

7h (HP Series 700) |

|

|

Enabled |

Enabled |

|

| On |

On |

On |

On |

Fh (Default) |

|

|

|

|

|

| Auto-stack |

The autoloader will enter Stacker mode after a magazine

has been inserted, and the first cartridge will automatically be loaded. |

| Auto-eject |

When the autoloader is in Stacker mode it will eject the

magazine after the last cartridge in the magazine is loaded. |

| Allow Resequencing |

While the autoloader is in Stacker mode, you can select

another cartridge to be loaded into the drive by using the Select and Load buttons. When

this option is not enabled, the Load and Select buttons are ignored in Stacker mode. |

| LUN 1 Magazine Ready |

A TEST UNIT READY command to LUN 1 will receive a NOT

READY status message unless a magazine is present and magazine cencus data is available.

When this option is not enabled, a TEST UNIT READY command will receive a GOOD status

report whenever the autoloader has completed the power-on self-tests. This provides a

method of detecting whether a magazine is present. |

| LUN 0 Drive Inquiry |

The product ID sent in response to an INQUIRY command to

LUN 1 will be that of the embedded tape drive. When this option is not enabled the ID sent

is that of the entire autoloader. |

|